Kyoho Technology

Oil analysis and filtration technology

Through analysis and diagnosis of all oils and greases used in our plants, we propose optimal usage methods, including recycling and reuse to help reduce industrial waste and lower running costs. The filtering equipment employed in recycling and reuse was developed in-house.

Oil separating system

We propose solutions for reducing production losses due to corrosion or machining defects through keeping machining equipment clean by removing oil from aqueous cutting fluids and cleaning fluids.

①Floated oil removing

This device uses a rotating drum and

compressed air to remove the oil.

The removed oil can be also recycled due

to the low water content.

②Oil separating

A cyclone flow is used

for forming oil droplets.

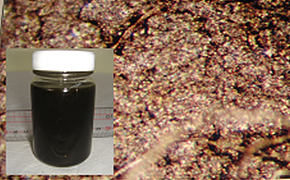

Recycling oils

Through analysis of the hydraulic fluid, lubricants, and cutting fluids used in equipment, we propose optimal cleaning equipment and recycling services to reduce waste and running costs.

Oil separating system

We propose solutions for reducing production losses due to corrosion or machining defects through keeping machining equipment clean by removing oil from aqueous cutting fluids and cleaning fluids.

Analytic equipment

Before cleaning:

NAS12 or higher (20 mg/100 cc)

After cleaning:

NAS5 or lower (0.5 mg/100 cc)

An article entitled "Maintenance of Machine Tools and Lubrication Control Points" was featured in the Journal of Economic Maintenance Tribology.